TRANSMISSION LINES WOULD BE ASSEMBLED BY INDUSTRIAL ROBOTS

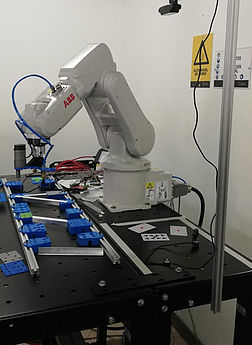

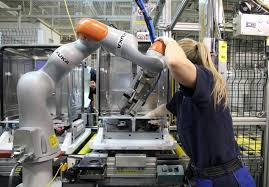

The automation of the scale assembly of a lattice tower for a 115,000 volt electrical transmission line marks the first phase of the prototype project of a fully robotic electrical substation construction model under Industry 4.0 standards. This project, developed through robotic tools and Open Source technology, proposes alternatives to automate the construction of an