The automation of the scale assembly of a lattice tower for a 115,000 volt electrical transmission line marks the first phase of the prototype project of a fully robotic electrical substation construction model under Industry 4.0 standards.

This project, developed through robotic tools and Open Source technology, proposes alternatives to automate the construction of an electrical transmission tower in a mechanized way, using a six-axis robotic arm and prototypes of automated mechanical systems that help assemble the parts. .

The proposal is part of the research line developed a little over 10 years ago by the T&T Group of the National University of Colombia Medellín and the Energy Distribution Company Enel – Codensa.

The initiative arose from the latter company, which sought to solve quality control problems and make up for the lack of qualified labor to build these transmission towers at height.

With the intention of improving times and reducing occupational risks, the project proposes the creation of three prototypes designed for the modular construction of the tower, which must be planned in great detail since it has dozens of pieces of different sizes and perforations that must be calculated millimetrically since failure in only one of them would cause delays and difficulties.

Professor Germán Zapata, the electrical engineer, and coordinator of the T&T Group Industrial Automation and Communications Laboratory, points out that it is a long-term project since it is working on a 25-year horizon when robotic lines are required for construction of substation structures and transmission lines due to a possible labor shortage.

As automation and robotization consist of implementing intelligent technologies to operate machinery and control a process, the 400 KV 4BR2 tower design was chosen to work at its operating voltage, the most used in the electricity sector.

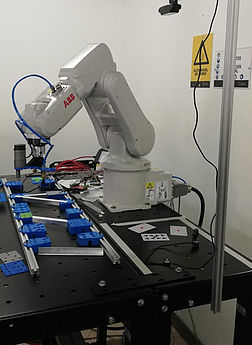

Subsequently, an industrial robot was selected to build a model, a technological mission was carried out to Japan, a leading country in robotics development and applications, and an industrial robotic arm was acquired, which today is located in the Automation Laboratory of the Faculty of Mines. .

Collaborative robots

Among the lessons learned, Professor Zapata highlights the opening of the robotics line of work, since “we had an automation laboratory without a robot; the acquired robotic arm was a consideration of the project, which remains the property of the University, for its application in teaching, research, and extension “.

He also recalls that they had to design the grip parts of the manipulator to perform the tasks and integrate other artificial intelligence technologies.

And since the idea is to emulate the behavior of the human arm to the maximum, one of the difficulties was having a single robotic arm, so cobots or collaborative robots will be needed to carry out the assembly in a synchronized way and without risk of collisions or blows with the humans.

Check out our collection of used robots and robotic parts at Used Robots Trade. We deal in used robots from trusted manufacturers like Kawasaki, ABB, FANUC, and more.