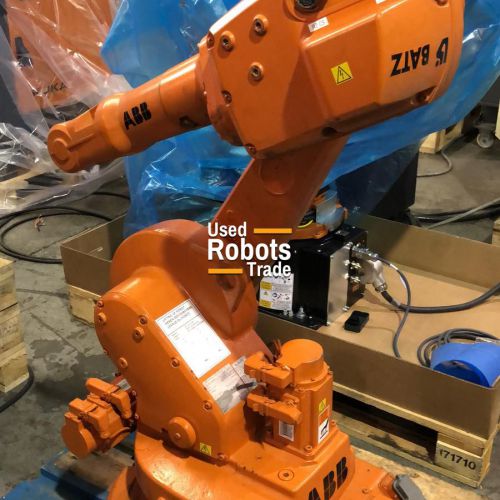

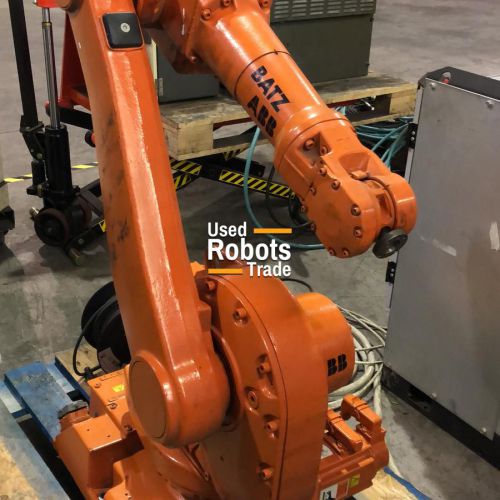

ABB 1600 M2004 10/1.20

Robot details

This industrial robot is excellent for a number of jobs that include handling of materials, machine tending, cutting, assembling parts, welding, moulding injection, die casting, packaging and measuring. It is six-axis and can handle weight of around 10kg and it’s arm can reach up to 1200 mm.

Advantages of the robot

IRB 1600 robot has over 50% lower cycle times compared to other robots that are used in handling materials, machine tending and other application procedures. It accelerates and slows down quicker than most robots. This helps the user to save time when working on tasks that require movements. It is made possible by the pantented QuickMove control of ABB together with the robot’s powerful motor. This robot expperiences low friction in its spur gears. The consumption rate is also reduced to a maximum speed of 0.58 KW. The noise produced is low and healthy to the sorroundings and a level of <70 dB(A).

IRB 1600 robot is made with IRCS M2004 controller and comes with the following features.

FlexPendant

This FlexPendant comes with a coloredtouch screen, which is clean and has 3D joystick that enables easy interaction.

RAPID programming

Rapid programming enables excellent combination of strength, simplicity and flexibiliy. It can be used with various structured programs and floor language. It supports numerous process applications and innovative features.

Communication and motion control

This robot’s control system supports I/O and can work with any network. It has strong networking features such as socket messaging and remote acess to the disk.

Robot applications

Main features

- Maximum Load of Robot: 10Kg

- Maximum Reach: 1200 mm

- Repeatability: 0.02 mm

- Controller: IRC5 M2004

Robot Motion Speed

- Axis 1: 180º/s

- Axis 2: 180º/s

- Axis 3: 185º/s

- Axis 4: 385º/s

- Axis 5: 400º/s

- Axis 6: 460º/s

Axis working range

- Axis 1: +180º to -180º

- Axis 2: +150º/s to -90º

- Axis 3: +65º/s to -245º

- Axis 4: +200º/s to -200º

- Axis 5: +115º to -115º

- Axis 6: +400º to -400º