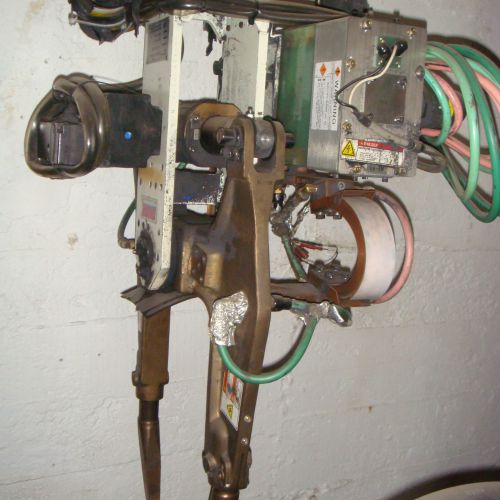

MILLER Auto-Axcess 450 Arc Welding Machine

Miller Auto-Axcess 450 Robotic Interface Inverter Welding Power Source, 190-639V Autoline with RMD Software

Specifications:

-Input Power: 3-Phase

-Rated Output: 450 A at 44 VDC, 100% duty cycle

-Output Power Range: 10 - 44 V

-Weight: 73.9 kg