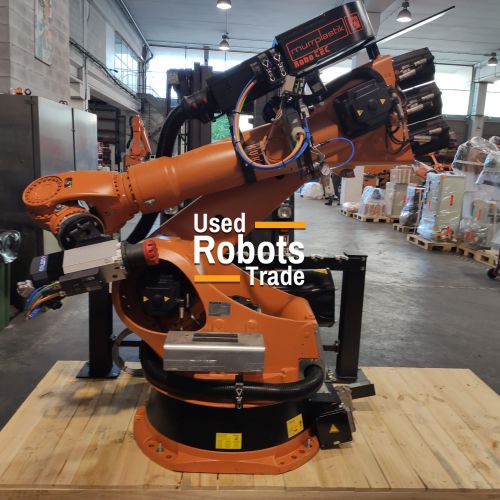

KUKA KR 180-2

Robot details

This class of heavy payload robots have three versions namely: KR 210-2 (2700 mm / 210 kg), KR 210L180-2 (2900 mm 180 kg) and KR 210L150-2 (3100 mm / 150 kg). They have 6 high torque axes and light arms which ensure that work is done fast with 0.1 mm accuracy.

The robot is suitable for machining, spot welding, handling and palletizing applications. More than one robot can be joined to work as a single system with improved communication.

Equipped with a powerful KR C2 ed05 controller system this robot is highly flexible. Programming packages are available to facilitate automation tasks while use of standard PC components allow both software and hardware customisation according to user requirements. The manufacturer has also provided plug and play functionality for rapid start up.

The system provides for monitoring through the internet together with a comprehensive safety concept. Diagnosis is also enhanced through data back up via floppy disk and CD-ROM drives.

Robot applications

- Press tending

- Loading and unloading of parts

- Machining

- Handling of parts

- Spotwelding

- Palletising

- Laser welding Nd-Yag

- Glueing - Adhesive bonding

- Stud welding

Robot Info

Maximum Load of Robot: 180/150/130 Kg

Maximum Reach: 2700/2900/3100 mm

Repeatability: 0.15

Controller: KR C2 Ed05

Axis Speed in º/s for the models: KR 180-2 / KR 180 L150-2 / KR 180 L130-2

Axis 1: 95º/s (all 3 models)

Axis 2: 95º/s (all 3 models)

Axis 3: 90º/s 87º/s 83º/s

Axis 4: 162º/s 168º/s 171º/s

Axis 5: 164º/s 168º/s 170º/s

Axis 6: 229º/s 235º/s 238º/s

Range of motion (Axis 1 to 6)

Axis 1: +- 185º

Axis 2: +0 to -146º

Axis 3: +155º to -119º

Axis 4: +-350º

Axis 5: +-125º

Axis 6: +-350º