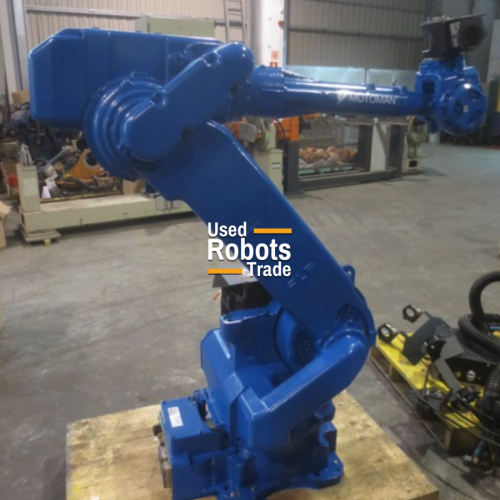

MOTOMAN UP50N

Robot details

The high speed UP50N is equipped with the latest NX100 controller which enhances performance. This robot was created 2008. It provides a good solution for industrial needs including handling, dispensing, material removal and press brake.

Having a 6 axis capability and 2046mm enables it reach widely and rotate enabling it big envelope coverage, keeping this machine up to the task. The long hours it can take in operation before any breakdown averages to 52000 hours. Together with its high repeatability, these factors make a machine that can be relied upon.

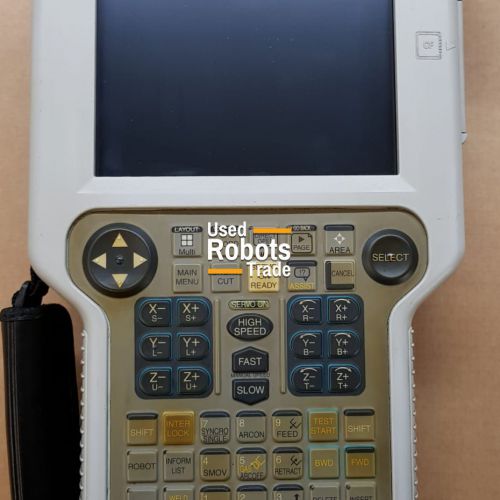

The PC based NX100 controller uses windows based system that is lightweight and user friendly. A full colour LCD touch screen display, which allows one to create their own personalised menu, enhances easy interaction with the programmer. Instructions and steps (numbering 10,000 and 60,000 respectively) can be stored and retrieved at with the best convenience. It also has a PC based robot controller, built in Ethernet and an accommodative architecture which enhance connection with external networks.

A maximum of four robots and their external axes together with I/O units can be controlled seamlessly using a single CPU. The design also factors in motion control software which ensures accuracy of path and reduces vibration. There is no need for a separate Programmable Logic Control (PLC) when using this system because improved PLCs are already integrated in the systems.

Another advantage is the reduced cycle time and ability to calculate robot axis torque that is only unique to Motoman products. Remote monitoring and diagnostics is also optimised in this robot giving better management of your machines with the least effort.

Robot applications

- Press tending

- Loading and unloading of parts

- Machining

- Handling of parts

- Polishing

- Laser cutting

- Laser welding Nd-Yag

- Glueing - Adhesive bonding

Robot Info:

- Maximum Load of Robot: 50Kg.

- Maximum Reach: 2046 mm.

- Repeatability: 0,07 mm.

- Controller: NX100

Robot Motion Speed:

- Axis 1: 170º/seg

- Axis 2: 170º/seg

- Axis 3: 170º/seg

- Axis 4: 250º/seg

- Axis 5: 250º/seg

- Axis 6: 350º/seg

Robot Applications:

- Handling

- Assembling

- Packaging/Palletising

- Grinding/Polishing

- Gluing/Sealing

- Cutting/Deburring

- Spraying/Painting

- Machine tending