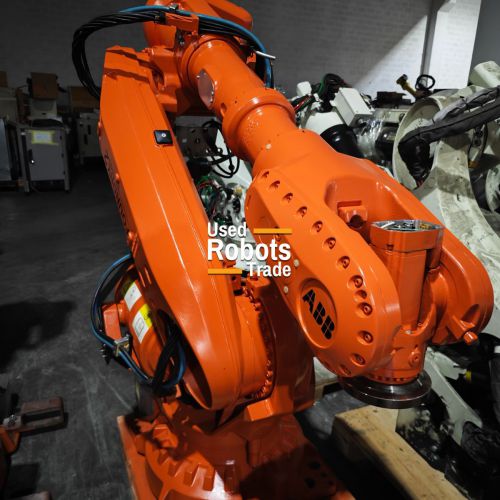

ABB IRB6700 155/2.85

Robot details

The ABB IRB6700 155/2.85 stands out as a high-performance industrial robot designed to tackle challenging tasks in diverse industrial environments. With a payload capacity of 155 kg and a reach of 2.85 meters, it combines robustness and precision, essential features in applications such as welding, heavy material handling, palletizing, and complex component assembly.

Equipped with the IRC5 controller.

One of the main advantages of the IRB6700 is its integration with the IRC5 controller, which not only offers an intuitive operator interface, but also includes advanced algorithms that optimize robot performance. The IRC5 incorporates technologies such as TrueMove and QuickMove, which improve motion accuracy and reduce cycle times, resulting in increased productivity.

In addition, the IRB6700 is designed to maximize efficiency and reduce operating costs. Its robust structure and Foundry Plus 2 technology make it ideal for working in harsh conditions, such as environments with high temperatures, humidity, or exposure to corrosive agents. This level of durability significantly reduces the need for frequent maintenance.

The IRB6700 is also compatible with a variety of tools and accessories, making it a highly adaptable solution to meet specific industry needs. From repetitive tasks to jobs requiring high precision, this robot has established itself as a key player in advanced industrial automation.

Robot applications

- Press tending

- Loading and unloading of parts

- Machining

- Handling of parts

- Arc welding

- Spotwelding

- Palletising

- Measurement

- Laser cutting

- Glueing - Adhesive bonding

- Assembly of parts

- Plasma cutting

- Spotwelding

Main features

- Maximum Load of Robot: 155 kg

- Maximum Reach: 2850 m

- Repeatability: 0.03 mm

- Controller: IRC5