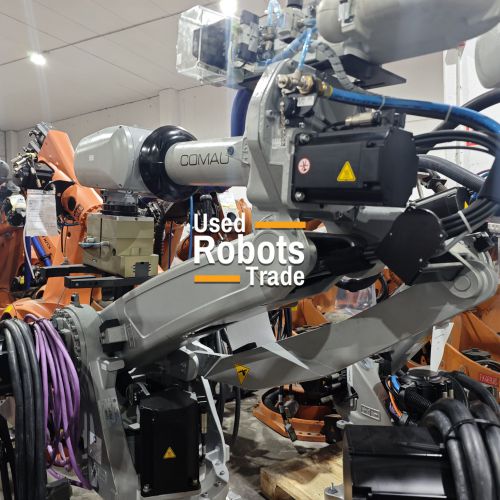

Other Robots Comau NJ 130/2.6

Robot details

The Industrial Robot NJ-130-2.6 is a 6-axis robot with a lightweight structure, a 130 kg payload, and a 2616 mm reach. It has more power, productivity, and energy efficiency than other robots, which reduces costs. It is suitable for welding, machining, assembly, and handling tasks. It comes with the C5G controller and the TP5 teach pendant.

The C5G controller is based on the latest industrial PC APC820 with a Core2 Duo CPU. It has low energy consumption and high performance.

The C5G controller has the following features:

• Energy saving: It has the lowest standby and operation consumption, a cooling system proportional to the control unit's operations, and an energy network recovery system with a high dynamic content program.

• Flexibility and reliability: It uses the new generation of field buses based on Hilscher technology, integrated by B&R in their remote I/O X20 family. It has modular interfaces for digital and analog I/O and various position transducers (encoder, resolver, etc.).

• Safety: It has an integrated SDM module, TUV certified (dual channel emergency stop, enabling device, logic drive enable), unbrake function on the robot arm, and interlock function for human-robot cooperation.

• Modularity / Expandability: It has a modular system for drives up to 13 axes in the base cabinet function of the power and the robot model. It can manage up to 16 axes in a multi-arm configuration with an application box.

• 3D off-line programming with Robosim Pro: It allows the creation and simulation of robot programs on a PC.

• Multi applications management: It can handle multiple applications simultaneously.

• C5G open controller: It allows the development of customized motion algorithms and special applications with sensors.

The C5G controller also has these main software functionalities:

• Automatic Payload Identification: It automatically identifies the payload to optimize the robot movement.

• Collision Detection: It stops the robot in case of a collision to protect the mechanic and the equipment.

• Cooperative and Synchronized Motion: It coordinates and manages several robots and auxiliary axes (linear track, servo gun, positioners, etc.).

• Conveyor and Sensor Tracking: It tracks parts in motion on linear and circular conveyors. It follows the path precisely with different types of external sensors.

• Joint Soft Servo Technology: It allows the robot joints to respond to external forces that are needed for the application.

• Interference Regions: It defines regions of various shapes to limit the robot working space.

• Robot Absolute Accuracy: It adapts the actual kinematics to the theoretical model programmed off-line.

Robot applications

- Press tending

- Loading and unloading of parts

- Machining

- Handling of parts

- Polishing

- Arc welding

- Spotwelding

- Palletising

- Measurement

- Laser cutting

- Laser welding Nd-Yag

- Assembly of parts

- Stud welding

- Plasma cutting

General technical specifications

- Maximum load of robot: 130 kg

- Maximum Reach: 2616 mm

- Repeatability in position: 0.07 mm

- Controller: C5G

Robot motion speed in º/s

- Axis 1: 110°/s

- Axis 2: 110º/s

- Axis 3: 110º/s

- Axis 4: 190º/s

- Axis 5: 190º/s

- Axis 6: 230º/s

Range of motion (Axis 1 to 6)

- Axis 1: +/-180°

- Axis 2: -75°/+95°

- Axis 3: -10°/-256°

- Axis 4: +/-280°

- Axis 5: +/-120°

- Axis 6: +/-2700°