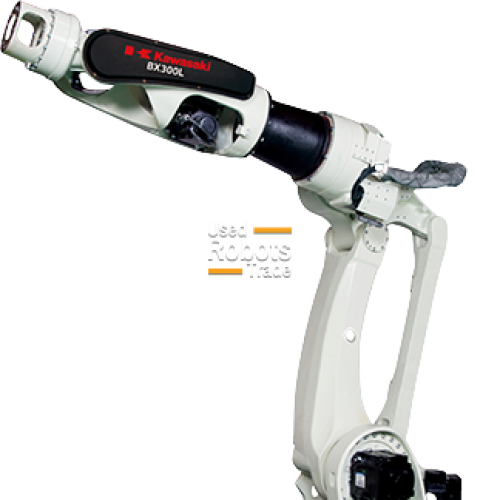

Kawasaki BX250L

Robot details

The Kawasaki BX250L robot is part of the B series and is designed with advanced technology to deliver high performance in spot welding applications. It features a wide range of motion and increased payload capacity, as well as a compact design that maximizes the work envelope. Its internal wiring system in the arm and high-tech motors optimize motion control and power, ensuring robustness and speed in demanding working conditions.

Controller E

E controllers are compact, reliable, and high-performance, equipped with advanced CPU technology that improves productivity and path control. They support a wide variety of industrial applications, thanks to Kawasaki AS technology, which uses a programming language for sequential control. In addition, they allow expansion of up to 10 external axes, providing full control of up to 16 axes. Their modular design and limited wiring facilitate maintenance and diagnostics.

- Ideal for primary power voltage distribution in different regions.

- Increased expansion capacity.

- Closed structure with indirect cooling system.

- Digital servo system.

- I/O channels: 32 (max. 128).

The combination of the BX250L robot and its E-controller offers an efficient and versatile solution for industrial welding applications.

Robot applications

- Press tending

- Loading and unloading of parts

- Machining

- Handling of parts

- Polishing

- Arc welding

- Spotwelding

- Palletising

- Measurement

- Laser cutting

- Laser welding Nd-Yag

- Glueing - Adhesive bonding

- Assembly of parts

- Stud welding

- Plasma cutting

- Spotwelding

- Milling

Main specifications

Maximum Load of Robot: 250 kg

Number of axis: 6

Maximum horizontal reach: 2,812 mm

Repeatability: ± 0.2 mm

Controller: E32

Motion range (°)

Axis JT1: ±180°

Axis JT2: +76°/-60°

Axis JT3: +90°/-120°

Axis JT4: ±210°

Axis JT5: ±125°

Axis JT6: ±210°

Maximum speed (°/s)

Axis JT1: 125°/s

Axis JT2: 120°/s

Axis JT3: 100°/s

Axis JT4: 140°/s

Axis JT5: 140°/s

Axis JT6: 200°/s

Robot applications

Friction Spot Joining

Machine Tending

Material Handling

Material Removal

Spot Welding