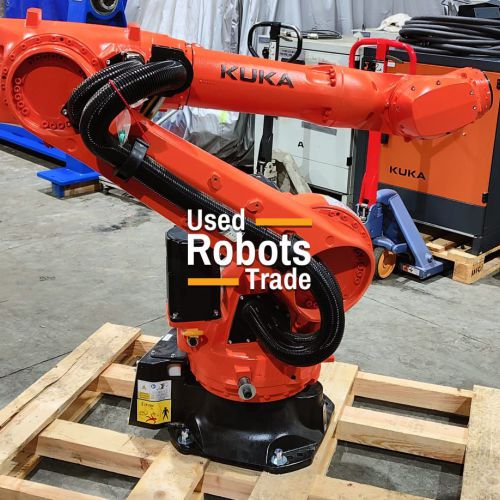

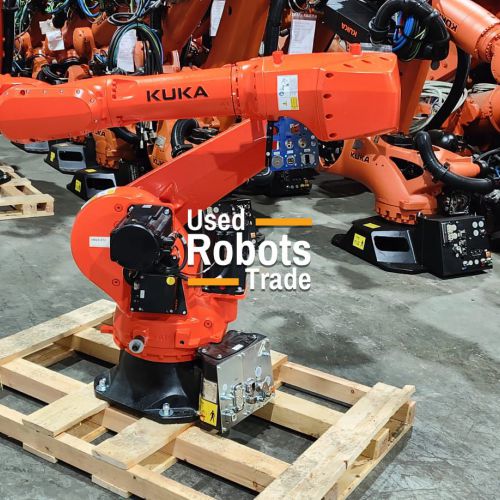

KUKA KR 30 R2100/SEL IONTEC

Robot details

The KUKA KR 30 R2100 is a 6-axis industrial robot with a compact design, with a wide operating range providing efficient use of space, its arm has IP65 degree of protection, that is, it is waterproof and dustproof, it adapts easily to any process or service, requires 50% less spare parts, fast learning with proven KUKA technology significantly simplifies commissioning; It is one of the robots with the highest productive level. It can be installed at an angle, ceiling, floor, wall.

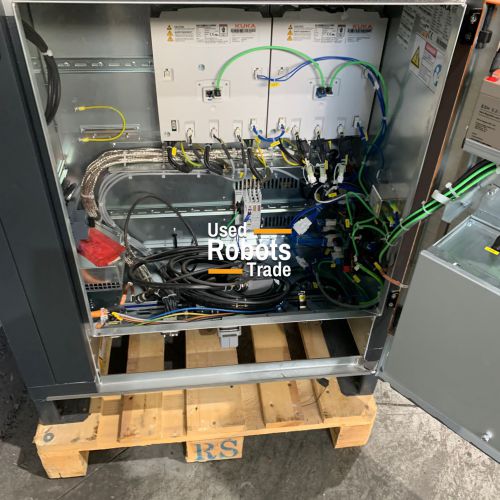

KR C4 - Kuka's latest breakthrough

More powerful, safer, more flexible, and above all more intelligent. The revolutionary concept of the KR C4 provides a firm foundation for the automation of tomorrow. It reduces costs in automation for integration, maintenance and servicing. The long-term efficiency and flexibility of the systems are increased at the same time. For this reason, KUKA has developed a new ground-breaking, clearly-structured system architecture that concentrates on open and powerful data standards. In this architecture, all integrated controllers – from SafetyControl, RobotControl, and MotionControl to LogicControl and ProcessControl – have a joint database and infrastructure which they use and share intelligently.

Robot applications

- Press tending

- Loading and unloading of parts

- Machining

- Handling of parts

- Arc welding

- Palletising

- Measurement

- Laser cutting

- Laser welding Nd-Yag

- Glueing - Adhesive bonding

- Assembly of parts

- Plasma cutting

- Spotwelding

Main specifications

Maximum Load of Robot: 30 kg

Number of axis: 6

Maximum reach: 2100 mm

Repeatability: ± 0.05

Controller: KR C4