Kuka kr6 R1611 krc4

Robot details

KR 6 Industrial Robot

The KR 6 industrial robot features a lightweight, aerodynamic design with a 6 kg payload capacity and a 1611 mm arm reach, providing excellent accessibility in confined spaces and optimizing cell space. It is characterized by its flexibility and versatility, offering a wide range of applications due to its various specific variables and mounting options, making it highly profitable in production environments.

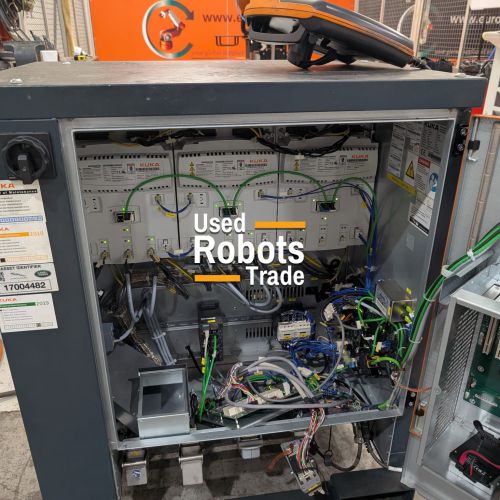

KR C4 - The Newest KUKA Controller

More powerful, safer, more flexible, and above all, more intelligent. The revolutionary KR C4 concept lays a solid foundation for the automation of the future. It reduces integration, maintenance, and servicing costs while enhancing the long-term efficiency and flexibility of systems. KUKA has developed a groundbreaking, clearly-structured system architecture focused on open and powerful data standards. This architecture integrates all controllers – SafetyControl, RobotControl, MotionControl, LogicControl, and ProcessControl – into a unified database and infrastructure, enabling intelligent sharing and use.

KR C4 Features:

- Simple to plan, operate, and maintain

- Continuation of proven PC-based control technologies

- Quick and easy operation with familiar control concepts

- Expanded command set for more user-friendly path programming

- High compatibility with previous KR C2 programs

- Integrated Safety, Robot, Logic, Motion, and ProcessControl in a single system

- Real-time communication between dedicated control processes

- Central basic services for maximum data consistency

- Seamless integration of safety technology for new applications

- Integrated software firewall for enhanced network security

- Innovative software functions for optimized energy efficiency

- Future-compatible technology platform without proprietary hardware

- Multi-core processor support for scalable performance

- Fast communication via Gigabit Ethernet

- Integrated memory cards for critical system data

- Designed for 400 – 480 VAC

- New fan concept for optimized energy efficiency

- Maintenance-free cooling without filter mats

- Highest performance in the smallest possible space

- Maximum availability

Robot applications

- Loading and unloading of parts

- Machining

- Handling of parts

- Arc welding

- Measurement

- Glueing - Adhesive bonding

- Assembly of parts

| VARIANTS | KR 6-2 C | KR 6-2 W | KR 6-2 | KR 6-3 |

| Maximum Load of Robot: | 6 kg | 6 kg | 6 kg | 6 kg |

| Number of axis: | 6 | 6 | 6 | 6 |

| Maximum horizontal reach: | 1611 mm | 1611 mm | 1611 mm | 1611 mm |

| Repeatability: | ±0,05 mm | ±0,05 mm | ±0,05 mm | ±0,05 mm |

| Controller: | KR C4 | KR C4 | KR C4 | KR C4 |

| Mounting positions: | Ceiling | Wall | Floor | Floor |

Motion range (°)

Axis 1: ±185°

Axis 2: +35°/-155°

Axis 3: +154°/-130°

Axis 4: ±350°

Axis 5: ±130°

Axis 6: ±350°

Maximum speed (°/s)

Axis 1: 156°/s

Axis 2: 156°/s

Axis 3: 156°/s

Axis 4: 343°/s

Axis 5: 362°/s

Axis 6: 659°/s