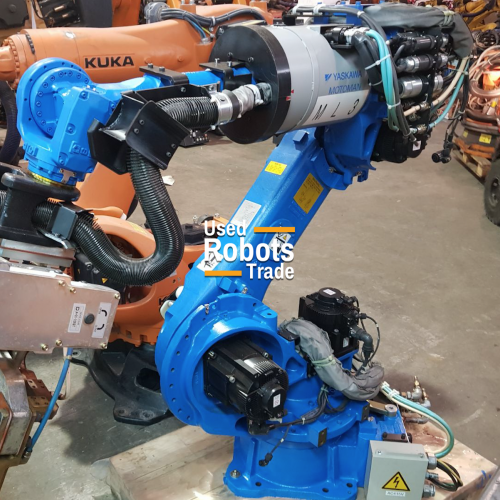

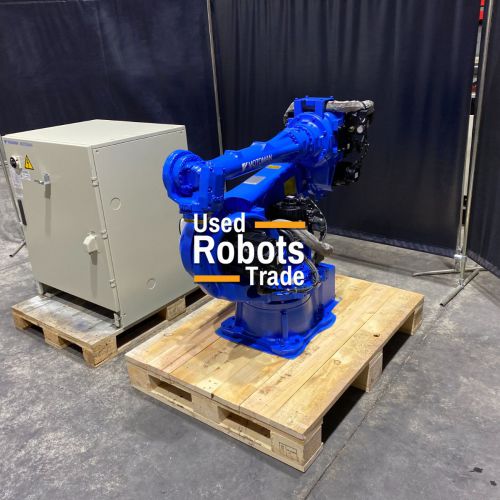

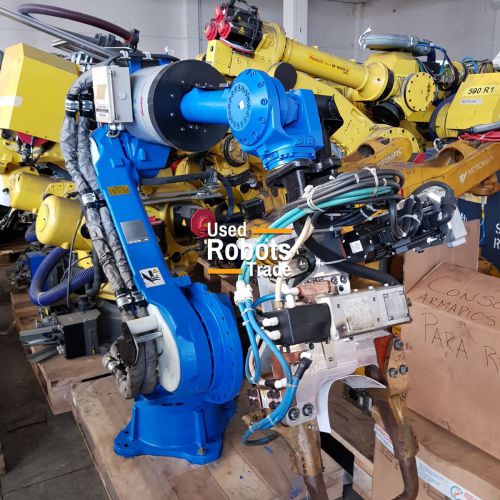

Motoman MS80W

Robot details

This robot used Motoman MS80 offers many advantages a for many applications such as spot welding and handling.This robot MS80 has undergone an intense refurbishment process and it is fully tested by our expert technicians.This robot produces fast movements thanks to his smart controller DX100, resulting in shorter cycle times and high throughput. Its smaller size allows it to be placed closer to the workpiece for added flexibility. The MS80 has integrated cabling and spot harness reduces interference and programming time. These cables and hoses are proven to last six times longer than traditional harnesses. This not only reduces maintenance, but it also improves the Motoman MS80 DX100 robot uptime.

Robot applications

- Loading and unloading of parts

- Handling of parts

- Arc welding

- Spotwelding

- Palletising

- Measurement

- Glueing - Adhesive bonding

- Assembly of parts

Main specifications

Maximum load of robots: 72 kg

Number of axles: 6

Maximum horizontal flow: 2.236 mm

Maximum vertical flow: 3.751 mm

Repeatability: ± 0.07 mm

Controller: DX100

Movement field (°)

S axis: ± 180 °

Axis L: + 155 ° / -90 °

U-axis: + 160 ° / -185 °

R axis: ± 205 °

Axis B: ± 120 °

T axis: ± 180 °

Maximum speed (° / s)

Axis S: 170 ° / s

Axis L: 140 ° / s

Axis U: 160 ° / s

Axis R: 230 ° / s

Axis B: 230 ° / s

Axis T: 350 ° / s

Robot applications

Spot welding