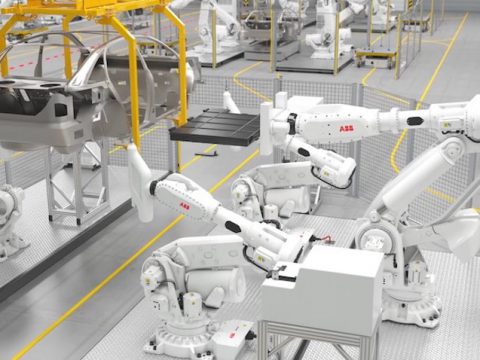

WHAT LEVEL OF PRECISION AND REPEATABILITY CAN I EXPECT FROM AN INDUSTRIAL ROBOT?

The difference between what the technical datasheets say and what actually happens on the shop floor “On paper it’s precise… but in real production?” One of the most frequent — and most honest — questions production teams ask is this: “Will the robot really be more precise than what we do today?” It’s not a