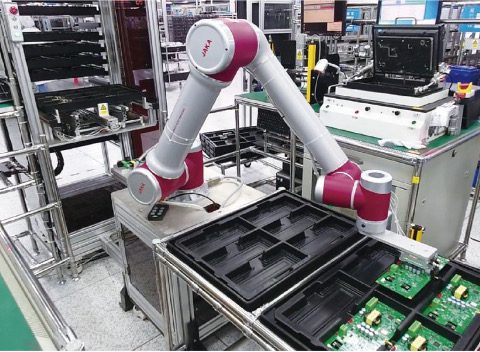

HOW COLLABORATIVE ROBOTS FROM DOBOT, JAKA AND OTHER BRANDS ARE REVOLUTIONIZING EDUCATION AND INDUSTRY

Collaborative robots, also known as cobots, are automation tools that work in collaboration with humans. Due to their ease of use, low cost and high precision, they are becoming increasingly popular in different sectors. In education, cobots are being used to teach students programming and robotics skills in an interactive way. For example, the Dobot