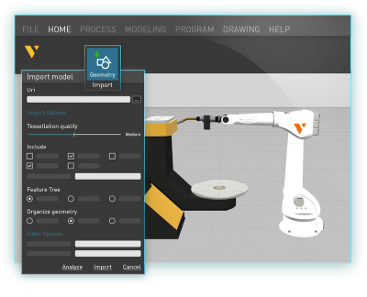

OPTIMISATION OF INDUSTRIAL SPACE: THE ROLE OF ABB ROBOTIC ARMS IN PRODUCTION PLANTS

In many factories, space is as valuable a resource as time or labor. Poor layout and inefficient use of space can lead to bottlenecks, downtime, and increased costs. In this context, ABB’s robotic arms have become a strategic tool for maximizing floor space, enabling production lines that are more compact, safer, and more efficient. Thanks