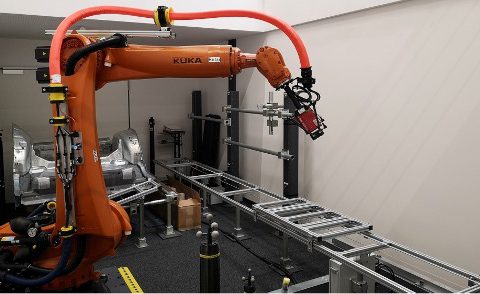

FOUNDRY ROBOTS MEET THE HEAT CHALLENGE AND HELP SUCCESSFULLY COMPLETE A WIDE RANGE OF TASKS IN A MORE PRODUCTIVE AND EFFICIENT MANNER.

The industry has seen great technological advances in recent years, especially in the field of robotic automation. Robotic arms have become essential in different sectors, such as the industrial sector. In particular, robots used in foundry processes have proven to rise to the challenge of heat and help successfully complete various tasks. Robotic arms for