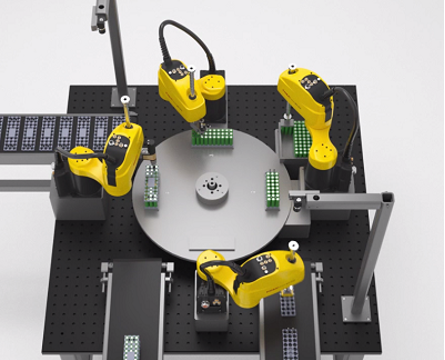

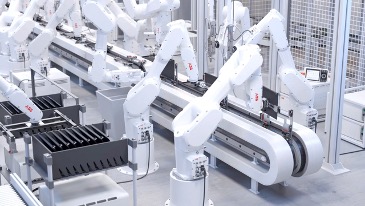

INNOVATION IN MOTION: THE FIVE ULTRA-FAST YASKAWA ROBOTS THAT YOU SHOULD KNOW

In the industrial robotics landscape, speed and precision are two critical qualities that drive efficiency and productivity on production lines. In this sense, the leading automation technology company, YASKAWA, has presented a range of ultra-fast robots that are redefining performance standards in the sector. With a combination of speed, precision and versatility, these five YASKAWA