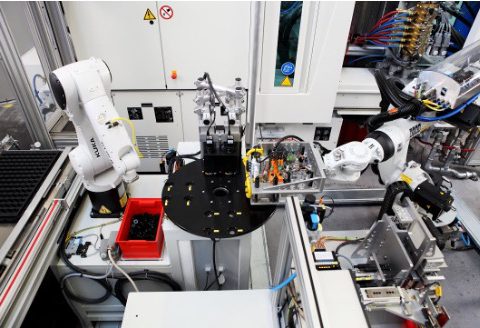

YASKAWA AND ROBOTICS UPGRADES ALLOW FOR IMPROVED CONTROL AND HANDLING WITH LESS ENERGY INVESTMENT.

The demand for effective robotic solutions is increasing as a result of increased automation, adaptation to new labor-saving production processes, and the repercussions of Covid-19. This is especially true in industries where logistics is critical, such as food, medicine and cosmetics, where the need to improve efficiency by automating the packaging and stacking of individual