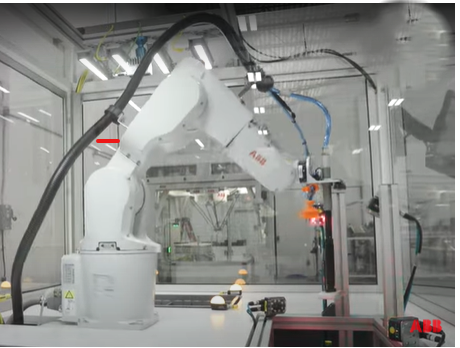

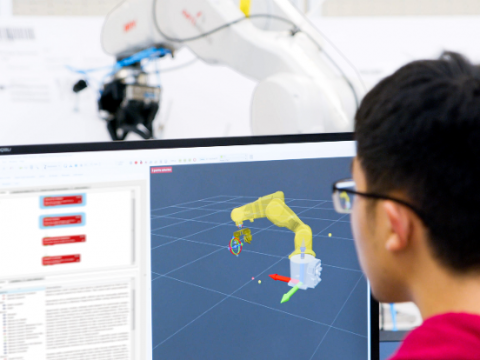

DISCOVER THE ABB ROBOTIC SELECTOR TO IMPROVE YOUR ROBOTIC SOLUTIONS

Hello everyone! Today I want to talk to you about the exciting launch of ABB, a leading industrial robotics and technology company. They have presented their latest invention: the robotic item selector. In this article, we will explore the various applications of this innovative technology and how it can revolutionize different industries. Automated item selection