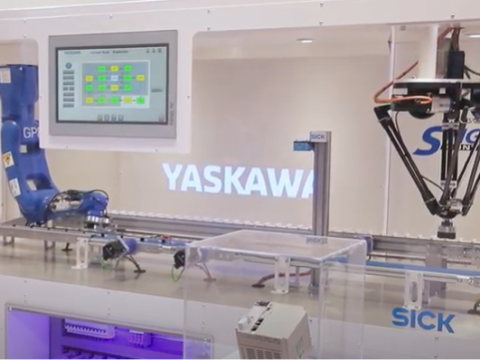

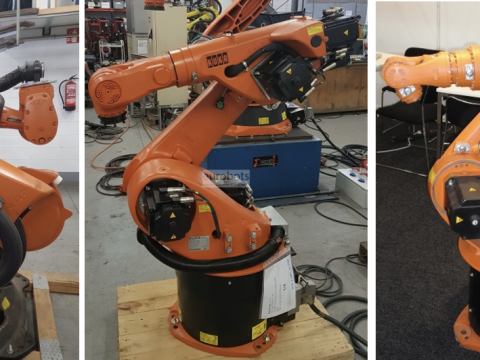

MOTOMAN UP6 A FLEXIBLE AND FAST SYSTEM

Line designers can now use one machine to perform multiple operations thanks to robots that are highly flexible and provide fast multi-tooling. The need to increase the efficiency of the production cells to obtain the largest number of operations in the smallest space. Plants in established car-producing countries cannot simply decide to increase their footprint.