HOW DO I KNOW WHEN TO STOP OPTIMIZING AND START PRODUCING?

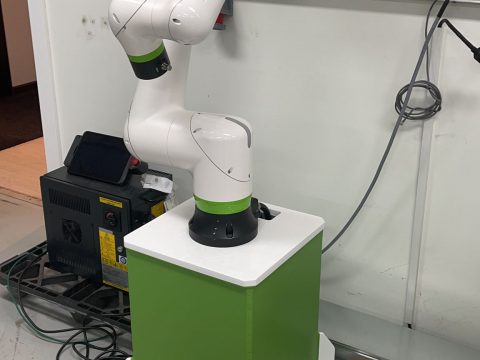

Some projects never fail: Because they never start! They live in a permanent state of improvement. Every week, the system becomes a little better than before—slightly more precise, a bit more elegant. There’s always something to tweak, something to polish, something that “before we start real production” should be optimized. The robot moves. The simulation