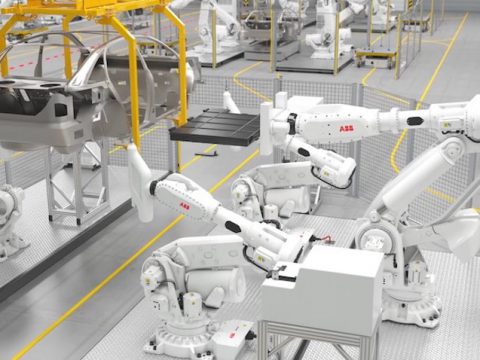

How Dependent Does My Process Become on Software Instead of Hardware?

This question rarely appears when a robot first arrives on the production floor. It emerges months later. When everything works. When the cell is producing. When nobody questions the arm, the gearbox, or the repeatability anymore. The doubt appears in front of a screen: A pending update. A license about to expire. A file that