With most industries looking forward to lean manufacturing solutions today, industrial robots provide a number of benefits that companies need to stay competitive in the long run. The reliability, speed and consistency offered by industrial robots helps ensures profits and productivity, cut down costs and contrary to popular belief, make room for employees.

But if all this while you were under the impression that for all this you need brand new industrial robots, then you were seriously misinformed. The refurbished industrial robots offered by our company can handle a wide variety of tasks and all sorts of complex situations where they will keep performing to the highest capacity.

Keep on reading to find out what sort of industrial applications our refurbished used robots are perfect for.

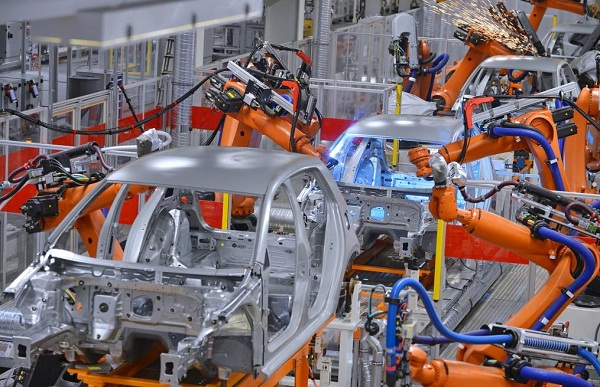

Assembly Lines

Assembly robots are especially common across industries that use lean manufacturing procedures. Automated assembly lines that are optimized for manufacturing with consistency and reliability range from automotive manufacturing to food processing. Here, robots don’t just help maintain accuracy but also assembly line speed.

Arc Welding

Arc welding industrial robots are mostly used in automotive and steel manufacturing plants. While human operators need to do the preparatory work, industrial robots handle heavy parts and perform the welding process. In addition to improving consistency in welds and enhancing production efficiency welding robots come with distinct safety advantages.

Welding mostly involves applying intense heat pressure to connect two pieces of metals and expose human workers to harmful fumes and there is also a risk of arc burns. Replacing human workers with industrial arc welding robots can help eliminate these risks.

Packing And Picking

The faster products are picked and packed off the assembly line, the better. However, this requires consistency and dexterity which can overtime tax the health and safety of workers along with decrease in efficiency and speed. Packing and picking robots ensure consistent output which is the reason why they are common across manufacturing industries.

Others

Although these are some of the most common application of industrial robots, there are a variety of others that are used in isolated and sealed environments to perform functions in contaminated areas. Moreover, there aerospace industries, food and textile industries also use water jet drills to cut and drill holes in materials.

Simply put, industrial robots are here and they are here to stay. In addition to the benefits secured by all these applications, used industrial robots also help cut down costs and come off as effective alternatives to their first hand counterparts.

At Used Robots Trade, we are a leading platform where you can purchase used industrial robots on highly competitive prices and get another step closer to automating your business operations. Feel free to get in touch with us for more information regarding industrial robots.