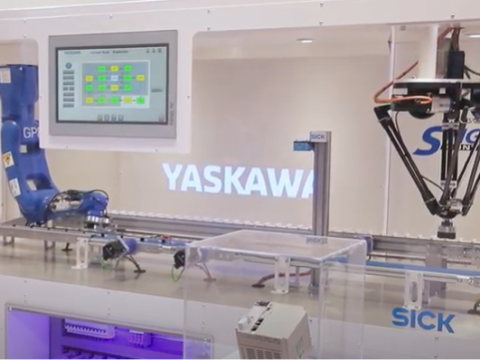

PROGRAMMABLE, FLEXIBLE AND EFFICIENT IN PALLETIZING

The Fourth Industrial Revolution has robotization and artificial intelligence in companies, two of the keys that will create a completely new ecosystem. The types of industrial robots available today in the industry are fully adapted to new needs. Currently, robots such as the AVG or Scara models have been updated to be able to serve