Robots have been revolutionizing business operations for over a decade now. Some of the principal factors that have contributed to the swift evolution in the field of robotics are:

Robots have been revolutionizing business operations for over a decade now. Some of the principal factors that have contributed to the swift evolution in the field of robotics are:

- Demand from the markets,

- Ecological preservation,

- Automation of industries, and

- Private services

Currently, robots are being utilized by the automobile industry, armed services, medical industry, farming, aerospace, literacy, and entertainment.

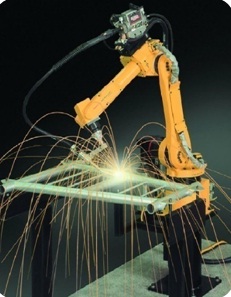

Within the field of robotics, the progression of arc welding robot has garnered a lot of attention. This scope of robotics has opened up doors, and researchers are delving into quite a few areas of improvement, such as its design, control system and sensing ability.

It is anticipated that robotic arc welding leave a very constructive impact on the overall production.

How Robotic Arc Welding Works?

Robot arc welding refers to the welding that takes place and is administered through robots. Generally speaking, robots that are designed for this purpose tend to be different from ones that perform arc welding manually.

Robotic arc welding usually involves heavy-duty cycles. That being said, the robotic arc must be able to function under these severe conditions. Moreover, gear components should possess essential features and tools to integrate with the main administrative system.

A dedicated kind of electrical power is needed to construct an arc weld. This power is supplied by a power source. Typically, all kinds of arc welding procedures make use of a gun/ torch (for arc welding) to send out welding current from the cable to the electrode. Moreover, it also protects and guards the weld space against the surrounding.

The spout of the torch is secured near the arc to smoothly and slowly pick the spatter. Then, an automatic torch cleaner is utilized in robot arc welds to get rid of the spatter. The unremitting electrode wire arc procedures necessitate a feeder to nosh the delicate electrode wire to the arc.

The welding equipment and modifiers grasp and locate parts to guarantee accurate welding by the robotic arc. The output level of the robot welding cell is made faster with an automatic rotator or switching equipment.

This allows the worker to mend a part set, while the robot welds a different one.

To ascertain that the tip of the electrode and tool frame is precisely in line with one another, the adjustment of the Tool Center Point is imperative. You can always use an automatic TCP adjustment tool to speed up this time-consuming activity.

Luckily, the long-standing advantages of a robotic arc welding process can be very constructive and helpful.

Moreover, most progressive companies have already invested in this arc welding robots to boost productivity. To join the league, turn to us and get hold of some best used robots. From Motoman to Fanuc and KUKA, we have a wide range of robots, arc welding robots, and spare parts for sale. For more information, call us at 0034 600 987 748.