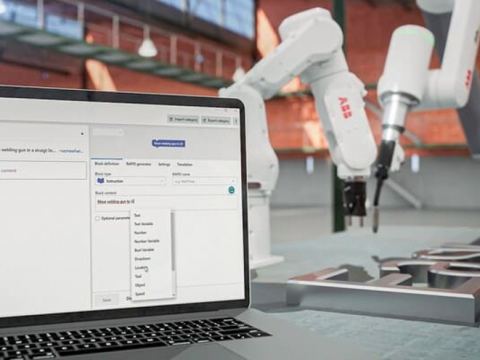

AUTOMATION AT AJAX METAL FORMING SOLUTIONS: A SUCCESS STORY IN ROBOTIC WELDING

Ajax Metal Forming Solutions, a prominent company in the metal stamping and fabrication sector, has taken a significant step towards modernizing its welding operations by implementing an advanced robotic work cell. This initiative has allowed Ajax to optimize its processes, improve product quality, and increase its market competitiveness. Challenges Before Automation Before adopting robotic technology, Ajax