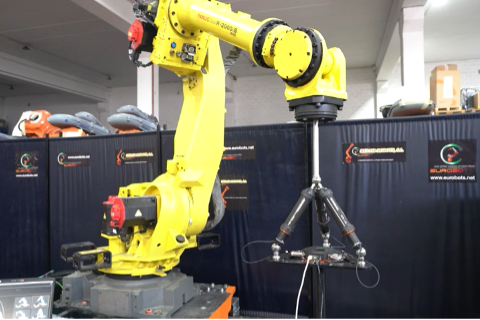

ROBOTS AND SAFETY IN INDUSTRY: KEYS TO A RISK-FREE PRODUCTION ENVIRONMENT

Currently, industrial robotics has transitioned from being an innovative solution to an essential necessity for maintaining competitiveness in the global industry. However, along with its increasing implementation, a critical priority arises: safety. Companies rely on robots not only to increase efficiency and reduce costs but also to ensure a safe working environment for employees. This