THE FUTURE IN AEROSOL: YASKAWA EXPERTS UNVEIL THE SECRETS OF ROBOTIC PAINTING AND COATING

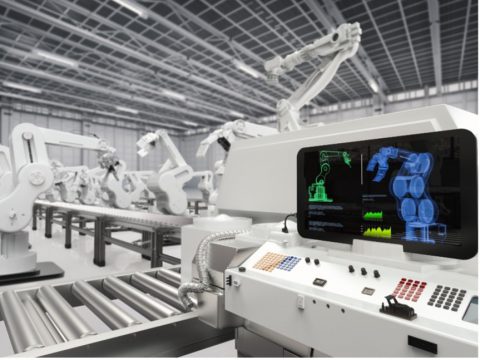

The industrial robotics industry is reaching new heights with every technological advancement, and painting and coating application is no exception. In the pursuit of optimal efficiency and quality, leaders in this field, like Yaskawa, are unraveling the secrets behind automating these processes. Aiming to shed light on this fascinating intersection between technology and manufacturing, we