THE FUTURE OF AUTONOMOUS INDUSTRIAL ROBOTS: TRENDS AND OPPORTUNITIES

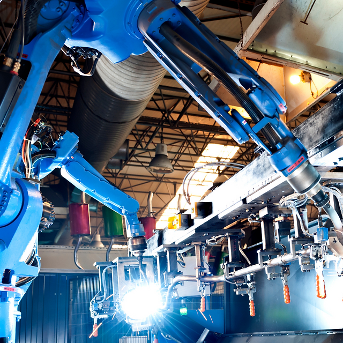

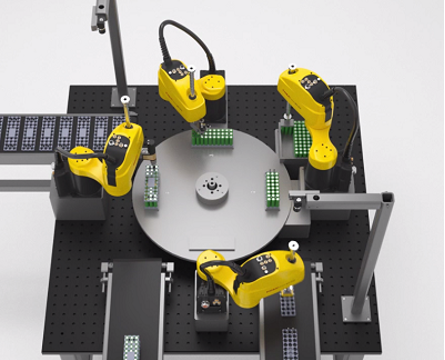

In the world of automation and robotics, autonomous industrial robots have become an essential tool to improve productivity and efficiency in various industries. These incredible devices are designed to carry out complex tasks independently, without the need for direct human intervention. Leading companies such as FANUC, KUKA, ABB and Yaskawa Motoman have developed a wide