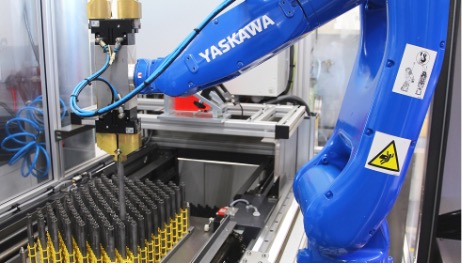

REVOLUTIONING INDUSTRIAL WELDING: THE LAUNCH OF THE MOTOMAN-AR3120 ROBOT BY MOTOMAN

In an exciting development for the industrial robotics industry, MOTOMAN has launched its latest creation, the MOTOMAN-AR3120 arc welding robot. This impressive device has captured the attention of the industrial world with its 20kg load capacity and exceptional reach of 3,120mm. The MOTOMAN-AR3120 promises to revolutionize welding processes in a variety of industrial applications. With