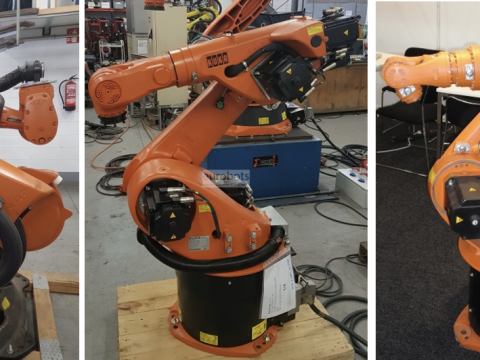

SUCCESS STORY TECHNOIDEAL AND ABB ROBOTS

Tecnoideal, an integrator for the medical industry, has just added new ABB industrial robots to its automated applications. After being acquired by Medica Srl, one of the first companies to provide worldwide consulting for the production of disposable products for dialysis and infusion, the company was transformed. From ideation, feasibility and design to installation and