Mass customization is all the rage in today’s world of manufacturing. Businesses are flocking toward offering personalized products to their customers to stay ahead of their competition.

Only a few decades back, the manufacturing sector was all about mass production. When Ford installed its first mass production line to build the Model T in 1913, it was the beginning of the large-scale production trend. Henry Ford reduced his production time per unit from 12 hours to 2.5 hours and made skyrocketing profits. Soon, high production volume at minimal production cost became the mantra for every business in the manufacturing sector.

This trend continued for a while until consumers started preferring customized products over the ones produced for the mass population. Today, mass customization is everywhere—and it wouldn’t have been if robots didn’t come into play.

If you’re still relying on mass production for your business success, it’s time to make the switch. Ahead, we’ve highlighted some important aspects of mass customization using robotics, in case you change your mind.

Mass Customization Won’t Reduce Your Production Efficiency.

It will increase it.

The manufacturing sector has been using robots to increase production efficiency for a long time now, but only with regards to mass production. When it comes to mass customization, there’s a widely accepted misconception. Businesses often assume that producing customized goods will take more time and cost, which will ultimately plummet their efficiency. But it’s far from the truth.

As explained by David Gardner, author of the book Mass Customization: An Enterprise-Wide Business Strategy, and Silicon Valley neoteric,

“I define mass customization as the ability to produce a single, customized product with the same efficiency as a mass-produced product.”

Modern industrial robots can be programmed according to the task nature and targeted production volume. Therefore, if appropriately integrated, they can make customized, low-volume production lines to new heights.

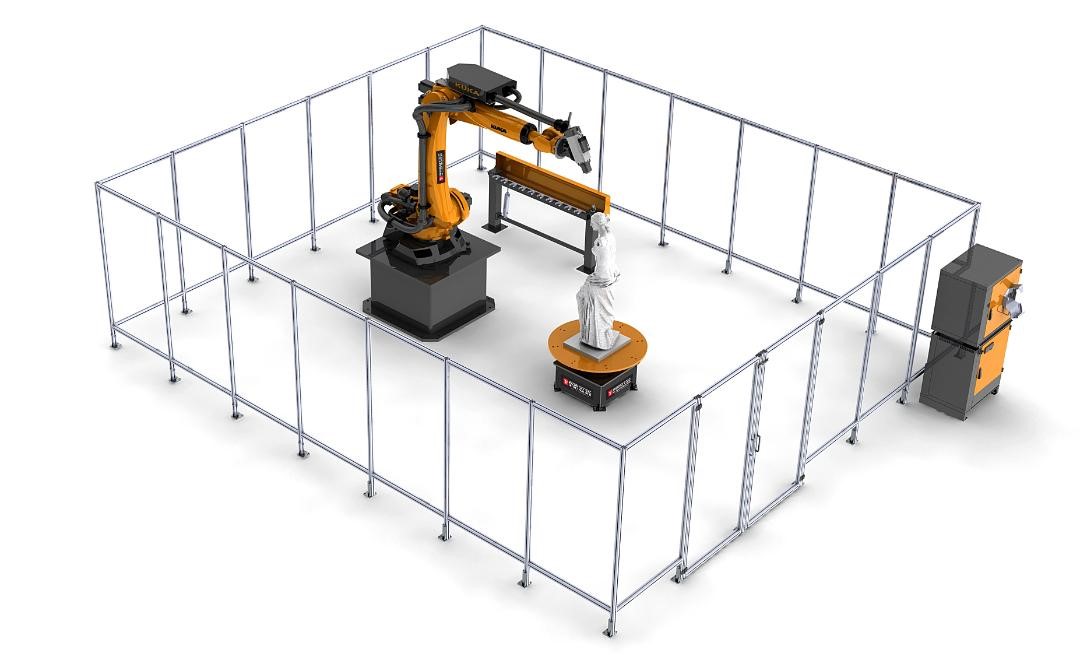

Robotic Cells Are the Modern Production Lines

If you want to shift to mass customization, you also need to modify your production processes. This modification includes drifting apart from the traditional assembly lines to smaller machining or milling robot cells for customized production.

Though robots are the primary element of these cells, they don’t need to be automated completely. Collaborative robots allow you to put in place a combination of automated and manual processes, which makes them ideal for mass customization.

Are you looking to enable mass customization in your business using high performing robots? Get in touch with us. At Used Robots Trade, we offer high-performing new and used industrial robots perfect for producing customized products quickly. We also provide the best robotic parts online and a range of robotic welding systems online for sale from top robot manufacturers, including KUKA, FANUC, MITSUBISHI, ABB, MOTOMAN, KAWASAKI, and others.