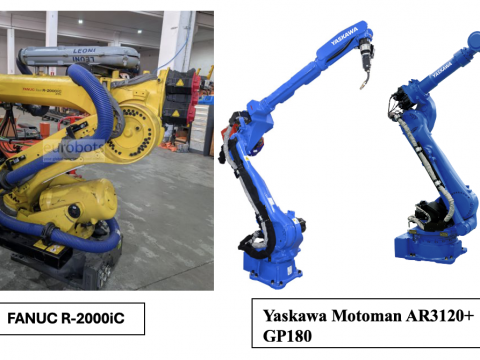

INTEGRATION OF YASKAWA MOTOMAN ROBOTIC WELDERS: PRECISION AND EFFICIENCY IN MANUFACTURING

Welding is one of the most critical and demanding processes in the manufacturing industry. Precision, repeatability, and safety are essential to ensure the quality of the final product. Yaskawa Motoman, known for its expertise in welding automation, has developed advanced robots and integrated solutions that optimize this process by reducing costs and increasing productivity. Models