Veo Robotics FreeMove system receives ISO 13849 safety certification from TÜV Rheinland. With the rise of collaborative robots (cobots) in the last decade, it seemed that the artificial intelligence trade would split into 2 divisions: one for the high-speed industrial robots we all know and one for cobots. Some robotic technology vendors would, of course, provide each type of robot, while others would focus on one space or the other.

Then something happened that attracted attention. Industrial robot vendors began experimenting with the concept of transporting cooperative golem capabilities to industrial robots. The first time I saw this it was shown as a draft idea on a very electric Mitsubishi booth at a trade event 5 or 6 years ago. At the time, I assumed this idea would proliferate rapidly; However, I didn’t see it again until I attended the SPS (Smart Production Solutions) event in Nuremberg, Germany in 2019. At this event, it was absolutely again at the Mitsubishi booth that I saw the technology on display. however, this point was not a part of a concept show, but rather as part of a debut between Mitsubishi and Realtime artificial intelligence.

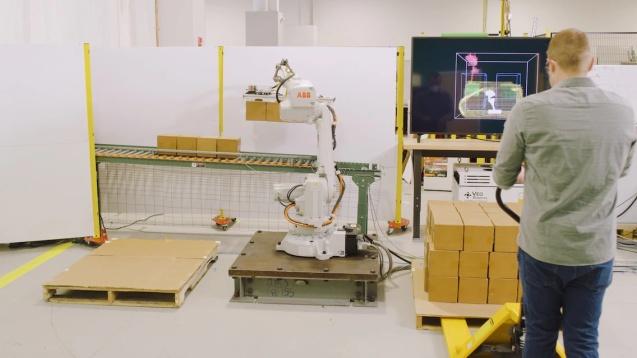

Many months later, on my last business trip before COVID-19 ended custom business events, I met with Veo Robotics Associate in Nursingd and learned that they were designing a system that would be able to bring cooperative capabilities to any industrial robot. Veo will do so with its FreeMove system, which uses multiple camera sensors and an algorithmic computing platform to reshape industrial robots into cobots. Veo maintains relationships with ABB, Fanuc, KUKA and Yaskawa, and its system is being applied and tested in the aerospace, automotive, appliance and construction instrument production industries.

A key part of embracing the technologies that promise to form cooperative industrial golems is overcoming the protection considerations of those who may be operating in close proximity to robots. Once everyone, if you’ve ever seen an Associate of Nursing industrial robot researching its high-speed steps in a heavily caged environment, you recognize that you don’t want to be anywhere inside that cage when the robot is running.

Such reservations regarding working so closely with industrial robots could now be about to disappear, as Veo artificial intelligence has just proclaimed that its FreeMove system has been certified for compliance with ISO 13849 for PLd, class three by TÜV. Rheinland. According to TÜV, ISO 13849 deals with the protection of all system technologies, as well as mechanical, hydraulic and gas products. Whenever safety functions are to be performed by safety-connected system elements (SRP / CS), the linear unit ISO 13849-1 usually demonstrates compliance with the essential health and safety laws of the Machinery Directive 2006 / 42 / EC.

“This can be a significant achievement for the team and therefore for the automation industry in general,” said Veo Robotics COO and co-founder Saint Patrick Sobalvarro. “After spending the last four years visiting factories, operating with our producer customers and building FreeMove, we have a tendency to be excited to be ready to provide the absolutely safety certified system.” He added that FreeMove is “the only answer on the market these days that implements dynamic speed monitoring and 3D separation.”

Are you looking for a robot parts supplier? Checkout“UsedRobotsTrade”for some of the best refurbished robots and robots parts. They also supply industrial robot spare parts as well as robotic welding systems from well-known brands such as Kuka, Abb, Motoman, Fanuc and Kawasaki. Get in touch with them today!