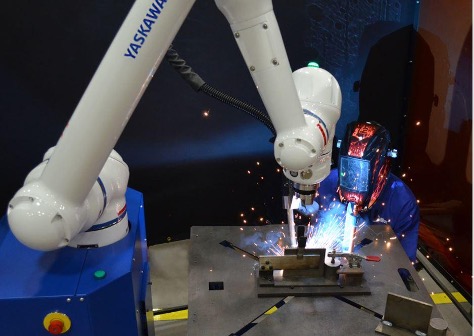

INTELLIGENT ROBOTS: YASKAWA ELECTRIC RAISES THE BAR WITH CUTTING-EDGE TECHNOLOGY

Yaskawa Electric MOTOMAN NEXT In an exciting breakthrough for the robotics industry, Yaskawa Electric Corporation has unveiled its latest achievement: the industrial robot MOTOMAN NEXT. This new robot is not only capable of performing complex tasks in unstructured environments but also makes autonomous decisions thanks to its advanced artificial intelligence (AI). How does it achieve