THE VISION OF LARGE-SCALE LASER CUTTING COMES A REALITY

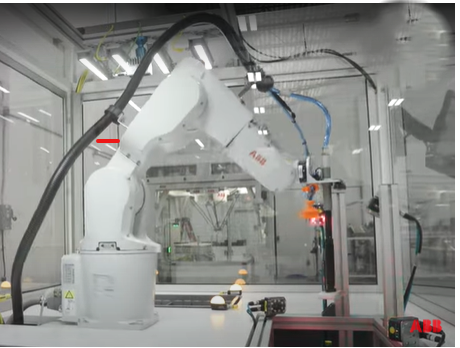

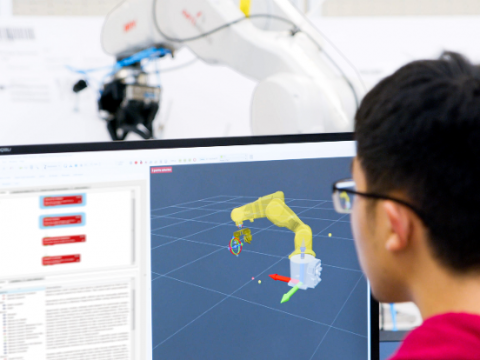

A suite of Fanuc automation solutions has proven essential to the delivery of an industrial-scale laser cutting cell commissioned by the UK Manufacturing Technology Center (MTC). Built by systems integrator Cyan Tech Systems , the demonstration cell consists of a 12m x 4m cutting table and, from Fanuc UK, a six-axis robot, a computer numerical