PLASTIC INJECTION MOULDING INDUSTRY

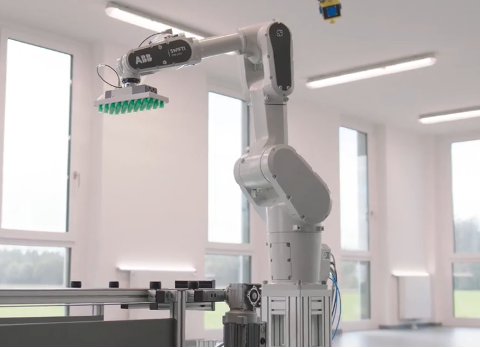

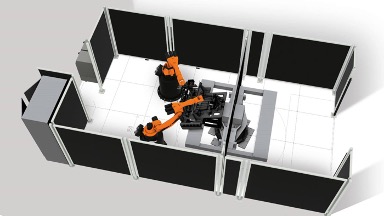

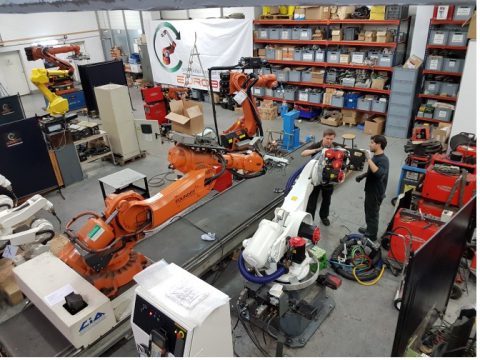

Typically, a gantry-type (also known as Cartesian, linear or transverse) top-mounted three-axis robot is used to demould injection moulded parts. Pick-and-place automation is commonly used to demould injection moulded parts. According to Fanuc Robotics programme manager for the plastics industry, Joseph Portelli, the demand for part orientation capability is increasing. However, today’s moulders are looking