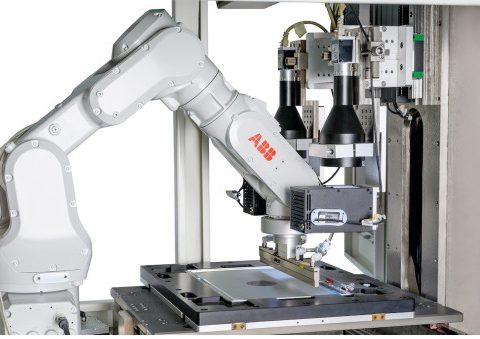

ROBOTIC INTEGRATION

Industrial robots improve productivity, product quality and efficiency, making them ideal for manufacturers large and small. Many companies looking to automate their applications cannot afford the upfront cost of new equipment. Using used industrial robots for new applications is an excellent way to minimize the cost of a project and increase the return on investment.