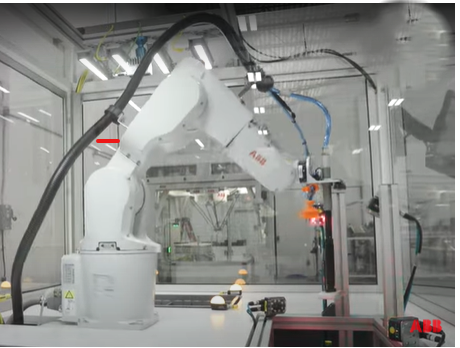

HOW ABB ARTICULATED ROBOTS ARE REVOLUTIONIZING THE AUTOMOTIVE, CHEMICAL AND MANUFACTURING INDUSTRY

Currently, the industry is undergoing an unprecedented transformation thanks to the automation of processes. In this sense, industrial robots have become a fundamental tool to increase efficiency and productivity in various areas, such as the automotive, chemical and manufacturing industries. ABB, one of the leading companies in the automation sector, has managed to revolutionize these