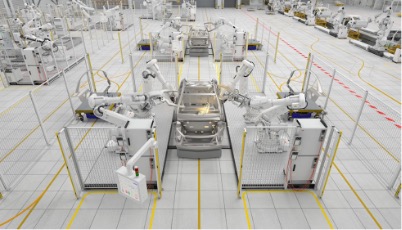

INCREASE RATE OF SERVICE ROBOTS

In today’s fast-paced world, technology is constantly evolving, bringing new innovations and advancements that change the way we live and work. One such innovation that is gaining a lot of attention is the rise of service robots. These robots, equipped with artificial intelligence and advanced functionalities, are revolutionizing various sectors, from healthcare to hospitality. THE