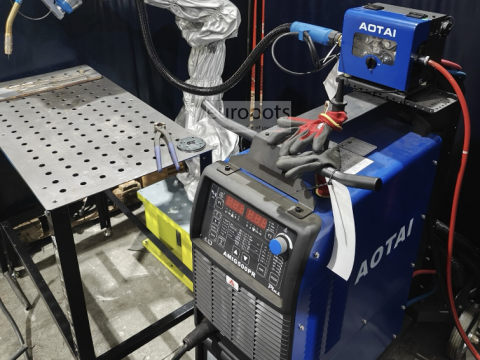

ADAPTIVE WELDING: ROBOTS THAT DETECT, CORRECT AND IMPROVE IN REAL TIME

The welding industry is undergoing rapid transformation thanks to the integration of advanced technologies like artificial intelligence and adaptive automation. Leading companies in the field are developing solutions that enhance precision, reduce reliance on specialized labor, and boost manufacturing efficiency. Among the most significant developments, three key trends are reshaping the world of automated welding—and