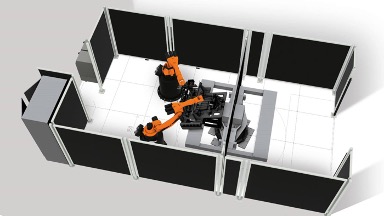

DEVELOPMENT OF INTELLIGENT AUTOMATION WITH KUKA ROBOTICS AND NOKIA COMMUNICATIONS TECHNOLOGY FOR 5G PRIVATE WIRELESS CONNECTIVITY

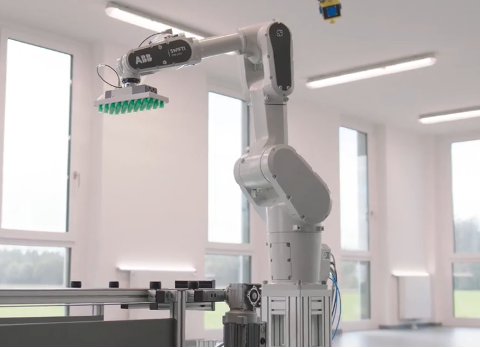

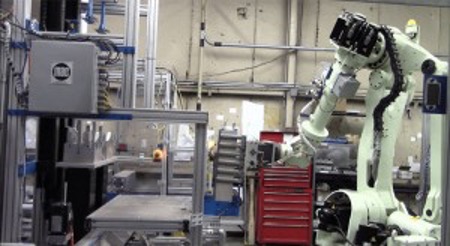

With its intelligent production and research centre in Augsburg, KUKA aims to introduce 5G autonomous private wireless networks, intelligent robots and automation technologies. The campus networking and application platform for Nokia’s Digital Automation Cloud (DAC) will start supporting product development immediately. The most significant advance in industrial networks is 5G, which should be widely available