THE SILENT REVOLUTION: HOW IA ROBOTICS IS TRANSFORMING THE MANUFACTURING INDUSTRY

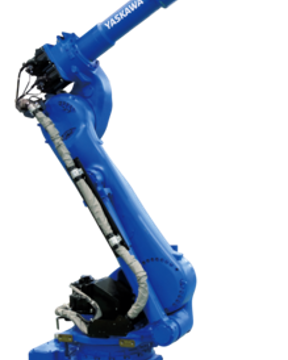

In the dark corners of factories, where lights flicker over assembly lines and the constant hum of machinery fills the air, a silent revolution is brewing. AI-powered robotics is emerging as an unexpected ally in the fight against labor shortages in the U.S. manufacturing sector. The Challenge of Labor Shortages The manufacturing industry faces a