DESIGN OF ROBOT ARM END TOOLS IT REQUIRES TAKING INTO ACCOUNT ADDITIVE MANUFACTURING

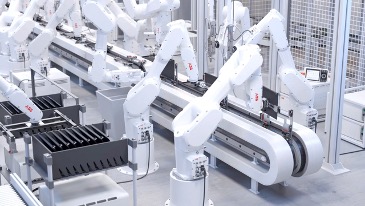

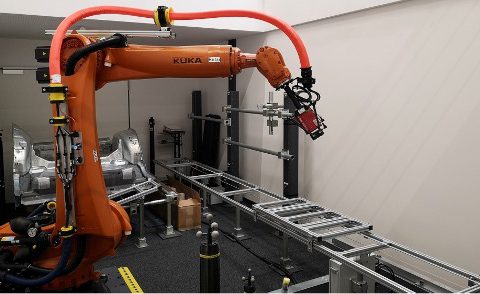

Numerous industries, from manufacturing to healthcare to transportation, have been transformed by advances in robotics technology. Robotic arms have become an important part of industrial processes, allowing automated tasks to be more efficient and accurate. The tools used at the end of the arm are essential for industrial robots to function properly. Traditional challenges in