ATX ROBOTICS: AN END-TO-END SOLUTION FOR AUTOMATED WELDING WITH UR ROBOTS

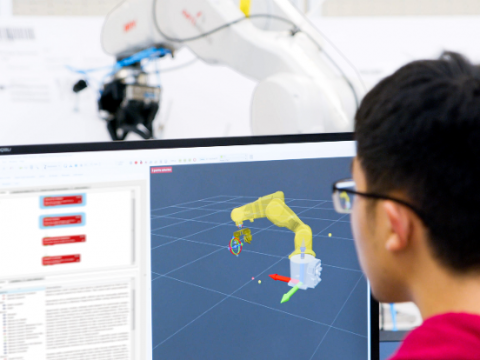

ATX Robotics, a division of the Aritex Group, has launched a modular collaborative robotics solution for welding, with the aim of improving productivity and making Industry 4.0 accessible to all industrial companies. The solution includes a welding machine, an automatable torch, Universal Robots UR10 or UR5 cobots, intuitive control software (URCap) and accessories. The cost-effective