RELOCATION OF PRODUCTION IS POSSIBLE WITH ROBOTIC AUTOMATION

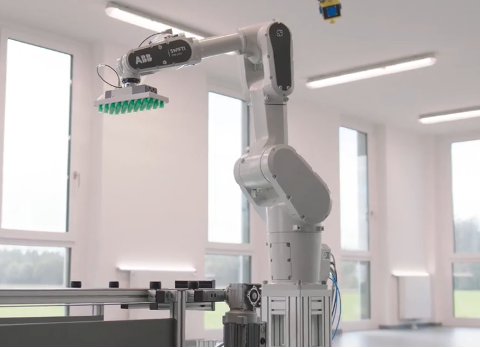

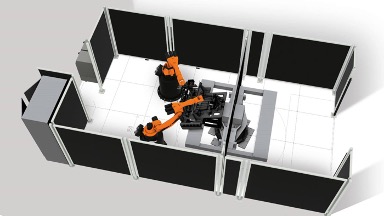

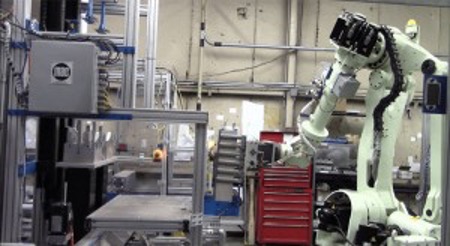

With rising international wages and increasing transportation costs forcing companies to reconsider the merits of maintaining production facilities overseas, the groundwork has been laid for the offshoring of US manufacturing. An important component of the equation is the newer generation of robots, and the environment in which this shift will occur reflects new economic realities.