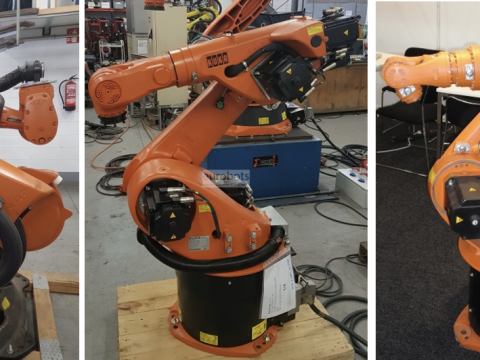

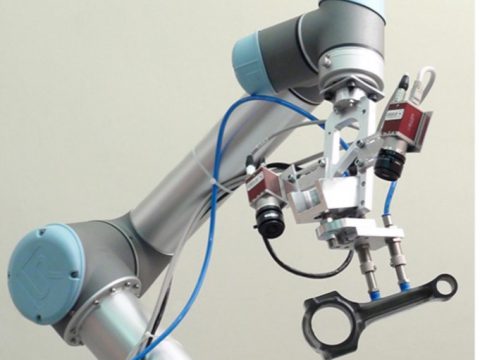

THE IMPULSE OF COBOTS IN INDUSTRY

Cobots that work alongside humans in automated processes are already in the future. Collaborative solutions are already transforming the way we operate and eventually the industrial world we know, whether they are used in production, storage, maintenance or training. They are also suitable for entry level automation applications because they are easy to develop and