ROBOTS AND ONLINE MEASUREMENT SYSTEMS: AN EFFECTIVE COMBINATION FOR QUALITY

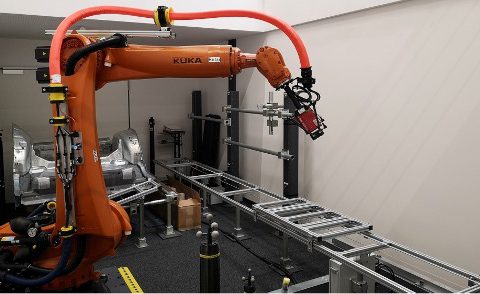

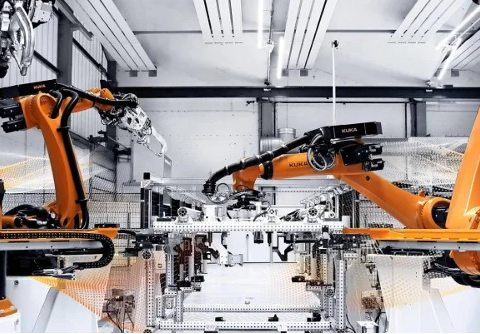

In-line measurement technology is a key tool for quality control and process optimization in the textile industry. However, this technology presents some challenges, such as the variability of environmental conditions, the complexity of materials, and the need for high precision and reliability. To overcome these challenges, the Spanish company Sumotex has developed an innovative system