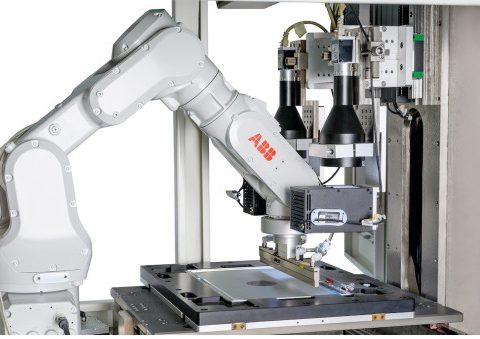

DIGITAL AND AUTOMATION INNOVATIONS FOR INDUSTRY

Through the monitoring of important assets and the elimination of repetitive and routine tasks, the integration of operational technology (OT) and information technology (IT) has helped companies to better regulate their operations. Traditionally, IT and OT have been created independently, making it impossible to use operations and production data for better workflow optimisation and well-planned