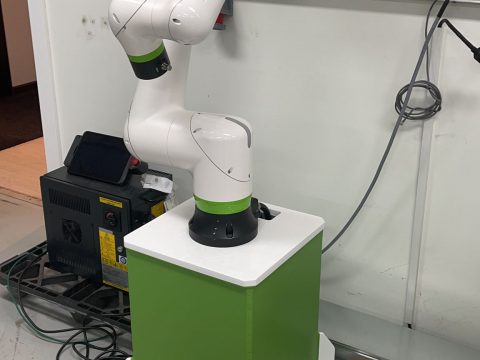

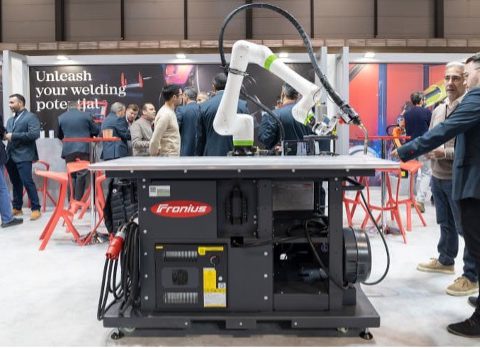

FANUC M-710IC/50: A MEDIUM-DUTY ROBOT AT THE SERVICE OF INDUSTRIAL FLEXIBILITY

In the world of industrial automation, medium-payload robots strike the perfect balance between strength and agility. Among them, the FANUC M-710iC/50 has earned a reputation as a reliable solution for processes that demand precision, speed, and adaptability. Backed by Eurobots, this model remains a competitive option for companies looking to enhance their operations with a